Trucking

Find your fit

Speed up your search for fall protection

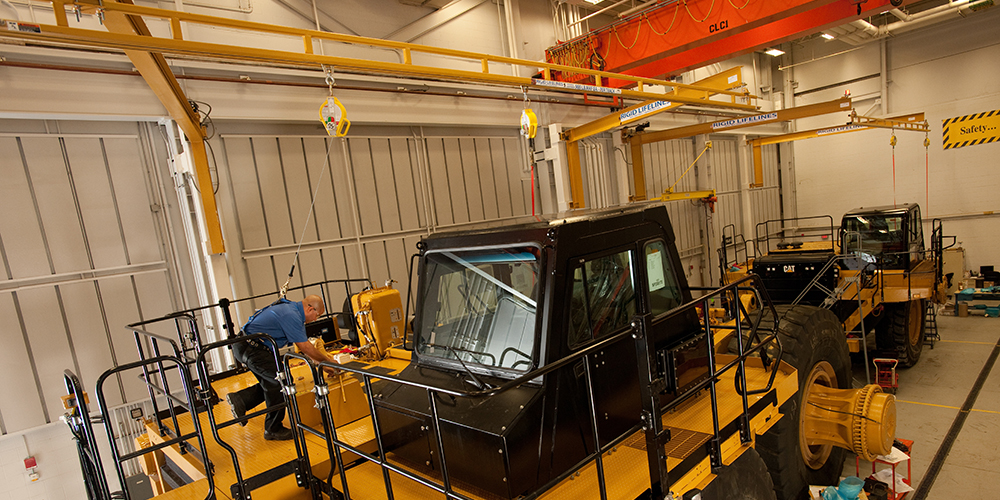

Implementing the proper safety protocols in the trucking industry can often be challenging because operations have many different moving parts. Besides applying to drivers and what happens on the roadways, safety measures in the trucking industry also cover the potential fall hazards when workers load or unload a truck. Using the correct fall protection systems is critical for preventing injuries and keeping workers safe when working at heights.

At Rigid Lifelines®, we design, engineer, and manufacture the industry’s top permanent and temporary fall protection solutions for a comprehensive industry range, including trucking. In addition to our standard systems, we offer customized solutions built specifically for your application’s unique requirements.

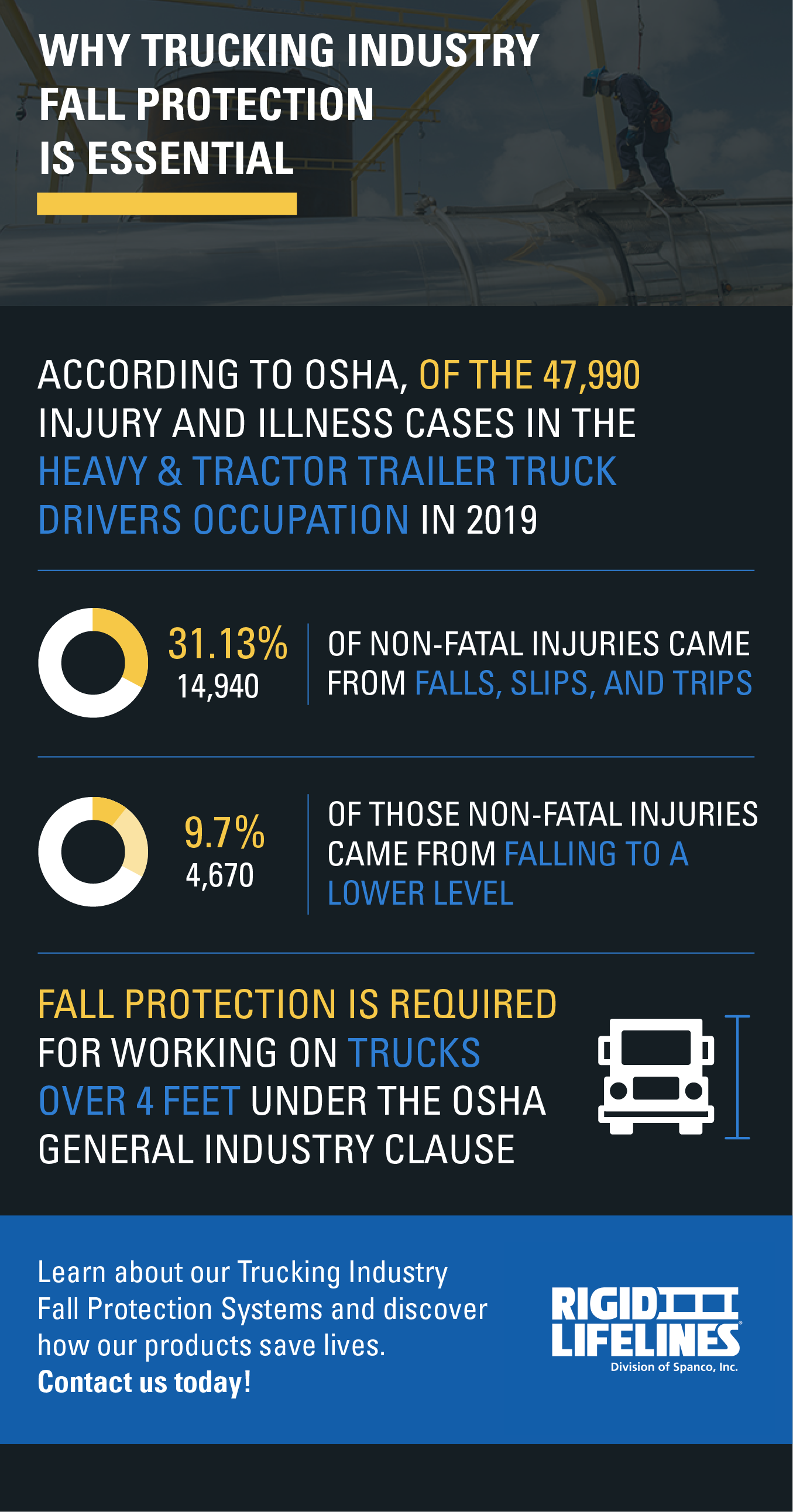

Why Fall Protection for the Trucking Industry Is Important

Workers in the trucking industry are often at a higher risk for falls because most of the tasks they perform are at elevation. Drivers require fall protection to enter or exit their trucks when their cabs are at certain heights off the ground. The same standards apply to employees working on an elevated loading dock without the proper safety features.

Different types of trucks have various access points, geometries, and potential fall hazards, from box trucks to flatbeds to tankers. Besides determining the minimum and maximum heights a driver or dock worker faces, safety managers must also consider a loading area’s layout and traffic pattern and whether it has all the necessary components for adequate protection.

Workers performing job tasks outdoors face additional challenges during winter, especially when contending with conditions like sleet or snow. If a driver needs to stop and secure an unstable load during transport on a flatbed, these conditions can be especially hazardous.

OSHA Fall Protection Requirements for Loading and Unloading Trucks

Under Occupational Safety and Health Administration Act (OSHA) Rule 1910, all general-industry employees must wear fall protection equipment when working at heights over 4 feet. Since job responsibilities in the trucking industry can encompass many different tasks, each requires careful safety coordination.

Because many forklift and material handling operations occur on the ground from start to finish, they do not require fall protection. However, whenever these workers need to perform a task on an unprotected platform over 4 feet, they must utilize the proper safety protocols. These regulations include dealing with unprotected edges and sides on a trailer if there isn’t a guardrail available to help workers maintain their balance.

Compliance for Truck Fall Protection and Safety

Rigid Lifelines® truck fall protection systems provide compliance for both OSHA fall protection and DOT/FMCSA regulations:

OSHA fall protection:

- 29 CFR 1910.28: Employers must provide fall protection at 4 ft or more above a lower level and protect employees from falling objects.

- 29 CFR 1910.140: Personal fall protection systems must include anchor requirements, connectors, harnesses, SRLs/lanyards, inspection, and use.

- 29 CFR 1910.30 and 1910.132: Training and PPE requirements apply to users and competent persons.

DOT/FMCSA regulations related to truck safety:

- 49 CFR 393 Subpart I: Cargo securement rules to prevent shifting/falling cargo — supports safer on-deck work

- 49 CFR Part 396: Systematic inspection, repair, and maintenance — aligns with safe access practices during service and inspection tasks.

Trucking Case Studies and Blog Posts

Find Your Perfect-Fit Product

Rigid Lifelines Fall Protection Trucking Flyer

Truck Fall Protection Systems: Ensuring Safety for Trucking Professionals

The trucking industry is a crucial part of transporting products for businesses. It is also a demanding job that carries safety risks. Tasks such as loading/unloading product, inspecting roofs, and servicing trailers can put workers at height, making safety regulations extremely important. These actions can often occur on slippery surfaces, while having workers in awkward positions handling unsecured loads can cause loss-of-balance risk, making truck loading fall protection necessary.

In 2023, workers in material moving and transportation occupations experienced 1,495 fatal work injuries, with falls, slips, and trips remaining a significant cause of death in the sector.

Rigid Lifelines® Truck Fall Protection Systems

Rigid Lifelines® offers engineered systems designed specifically for truck and trailer work at height:

- Mobile anchor points: Rigid Lifelines® provides portable, engineered anchorage systems that bring a certified anchor to the work, enabling restraint or fall arrest without a permanent overhead structure. These are typically used during flatbed tarping/untarping lanes and load securement checks to provide flatbed truck fall protection.

- Horizontal lifelines (HLLs): HLLs are engineered, tensioned lines, typically overhead, that allow users to move along a truck lane or bay while remaining tied off. They are best used for tanker truck fall protection on long runs, such as tanker tops, flatbed lanes, and service bays, where continuous lateral movement is required.

These systems are available as either permanent or mobile solutions, depending on your facility’s needs.

Permanent Solutions

Our permanent solutions are ideal for businesses with a stable work environment where tasks are repeatedly performed in one location. Permanent solutions can affix to the existing structure, making installation simple.

One example is a Ceiling-Mounted Monorail, which attaches to the supports and takes up no floor space. Our Ceiling-Mounted Monorail Anchor Track™ System lets you get the most out of your workspace and keep the area clear of equipment.

Mobile Solutions

Mobile fall protection systems are available for rented spaces, areas where the hazard changes locations, or times when you need to move your equipment between sites quickly. These portable systems can be carried by forklift or towed with a durable pickup truck.

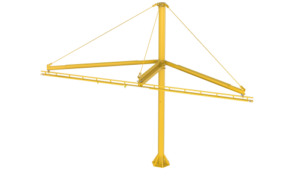

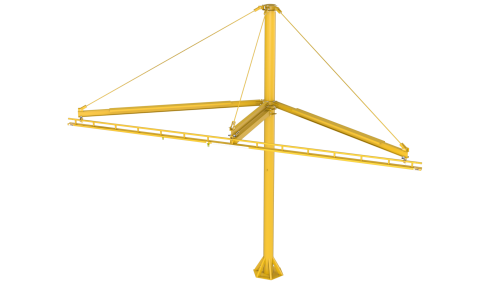

The Griffin™ is one of our popular mobile options. It is available with either wheels or skids at the base. With either option, the workers are attached to the device’s extended arm and can move freely to complete their tasks.

Why Choose Rigid Lifelines® for Truck Fall Protection Systems?

Rigid Lifelines® offers a comprehensive selection of permanent and mobile fall protection systems for your trucking operation, keeping you compliant with industry regulations while maintaining your company’s efficiency and productivity. All our solutions meet standards established by OSHA and the American National Standards Institute (ANSI).

For decades, we have worked with some of the most recognized names in the trucking industry, offering advanced solutions that maximize safety for loading, unloading, and other everyday tasks common in these operations. Because we understand that no two trucking operations are alike, we offer tailor-made fall protection systems specific to your application’s safety needs.

With manufacturing facilities on the East and West Coasts, we can provide customers with the streamlined service and individualized attention they deserve. We also offer some of the industry’s most comprehensive product warranties.

Connect With Us Today to Learn More

Falls from trucks are preventable. With engineered systems like Rigid Lifelines® mobile anchors and horizontal lifelines implemented alongside sound procedures, training, and cargo securement, you can protect your team, improve productivity, and demonstrate compliance with OSHA and DOT requirements.

If your trucking operation requires an advanced permanent or mobile fall protection solution, trust Rigid Lifelines® to cover all your needs. Our vast industry knowledge lets us stay current with existing codes while pursuing solutions that improve safety and work efficiency. Contact us online or find a representative near you today for a quote or additional product information.