System Selection Guide: How to Choose the Right Fall Protection System

February 3, 2025

If you’re looking to install a comprehensive fall protection system for workers, follow this simple system selection guide to help identify the best system for your application. After you have supplied a brief answer to the questions listed below, you can move through the rest of the selection guide to provide exact specifications for your fall protection needs.

Things to Consider Before Moving Through the Steps Below:

- Which area of the facility requires fall protection?

- How many workers will be using the system at one time?

- Does your application require workers to be able to pass one another while attached to the system at the same time?

- How will the system be supported?

- What type of lanyards and harnesses will you need to supply?

- Where will workers initially connect to the fall protection system? Is there a location for a tagline to hang down without interfering with an overhead crane or other equipment? Can a tagline be stored out of the way or in a location that is easily accessible for workers?

- If a worker falls off the edge of a work area, how many degrees off-center will the lanyard line be?

- How will you rescue a fallen worker?

Questions to Ask When Evaluating the Workspace

When a Competent Person is evaluating a workspace for potential fall hazards, there are several very important questions that workers need to ask themselves because the answer to those questions will directly correlate with the type of fall protection equipment that should be used in that location.

While evaluating a workspace, you’ll want to ask yourself the following questions:

Do workers need to access the area at height in order to do their job?

Why we ask this: If it’s possible to eliminate a worker’s exposure to the height, it’s best to pursue that course of action.

How many people will need to access the workspace?

Why we ask this: This helps fall protection professionals determine how many workers will need to be supported on a horizontal lifeline system. This question also helps establish how many people will need to be trained in using the system.

Can the area be protected with guardrails or another form of passive fall protection?

Why we ask this: If a form of passive fall protection can be used, this reduces the need for people to have fall protection training and it makes the area at height safe for almost anyone to access.

Are there obstructions or other things that could cause a swing fall in the potential fall paths?

Why we ask this: If there are things that a worker might hit if they were to fall, fall protection professionals will make sure that they choose a system that will either eliminate the potential for a swing fall or accommodate the potential obstructions in another way.

Will workers need to have vertical or horizontal movement while working in the area?

Why we ask this: If a worker needs to move vertically (ex: ladders, scaffolding) while they are working, they will need to use a vertical fall protection system. And, if workers need to move horizontally through their space, a horizontal fall protection system will be applied.

Could the support structures potentially support a permanent fall protection system?

Why we ask this: If the area surrounding the workspace can’t support the weight of a rigid track horizontal lifeline fall protection system, then a different solution may need to be used.

Will rescue be possible?

Why we ask this: Depending upon the location of the worksite, it’s important to try and put a fall protection system in an area where a worker can be easily accessed by a rescue team after a fall.

Step 1: Coverage Area and Hook Distance

To identify the best system for your particular needs, start by specifying your required coverage area and hook distance. In other words, consider the following questions:

1. Where in your facility do your workers need fall protection?

2. Calculate the length, width, and height of that specific area.

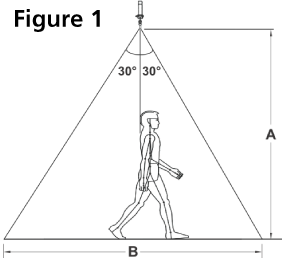

- You can reference our height to coverage width calculator below to determine height requirements for your facility. It’s important to note, however, that most Rigid Lifelines’ Anchor Track systems allow workers to be 30 degrees off plumb (also known as off center).

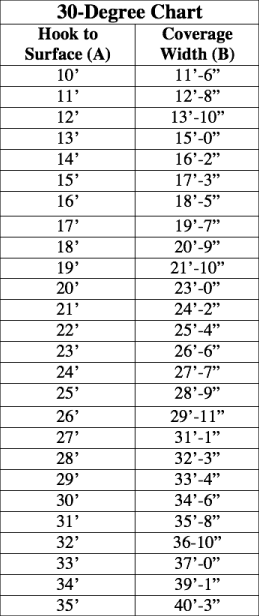

The height to coverage width calculator helps you to determine your coverage area and hook-to-surface distance. Use the chart below—along with the coverage drawing (Figure 1)—to determine your coverage area and hook distance:

Step 2: Worker Capacity:

After you’ve determined your coverage area and hook distance, you will need to determine your worker rating for the system. Your worker rating will depend on how many workers you will need to attach to the system at one time. At this point, you will also want to consider whether or not your workers will need to pass one another while attached to the system.

- To calculate your worker rating for the system, first decide how many workers will need to attach to the system at the same time.

- Keep in mind that 900 pounds of maximum arresting force (MAF) is considered the threshold for injury. In other words, if your maximum arresting force on each worker is 900 pounds or less, the potential for injury in the event of a fall is far less.

- Keep in mind that 310 pounds is the standard maximum working load capacity allowed per user by OSHA and ANSI standards, meaning system tests are conducted to simulate arresting the fall of up to a 310-pound worker. 310 pounds includes the person and any tools. If the working load including tools exceeds 310 pounds, then special equipment and/or a higher system rating must be used. Special equipment would be full-body harnesses and self-retracting lanyards rated for more than 310 pounds.

Step 3: Permanent or Mobile Fall Protection:

The next step in selecting the right fall protection solution is to decide which type of system your application requires. This process includes deciding whether your operation needs a permanent or mobile system. In addition, it’s important to take the following information into consideration before moving to the next step.

1. Permanent fall protection systems can be mounted to ceilings, walls, or the ground to provide a constant fall arrest solution. Permanent systems are critical for workers who are exposed to or working at heights in the same location. Ask yourself, are there any obstructions that would prevent mounting a continuous system? Are there obstructions that would prevent the travel and operation of a self-retracting lanyard (SRL)?

- If you have decided that your application requires a permanent fall protection system, you will need to consider the best way to mount your system according to your facility and operation. In other words, does the track need to be mounted overhead to an existing ceiling structure? Or, is there a column near the specified coverage area that can support the weight of a column-mounted system? Or, is there floor space next to the specified coverage area to place a freestanding column or multiple columns?

2. Mobile (or portable) fall protection systems are ideal for temporary work stations. By using forklifts, heavy-duty pickup trucks, or workers, you can move our mobile systems to any location that needs fall protection. Mobile systems do not require any type of foundation or mounting, and they provide the convenience of mobility without sacrificing the reliability of rigid track. Ask yourself, is there enough space on the ground near the specified coverage area to place a portable base? Do you have a forklift with the capacity to move the counterweighted system? If there isn’t enough space for a portable base or a forklift with the required capacity, is there enough space on either side of the coverage area to place wheeled uprights?

- If you have decided that your application requires a mobile fall protection system, you will need to consider the best way to move the system from one location to another—depending on your individual needs. In other words, will you need to move the system with a forklift or by hand? If you prefer to move the system using a forklift, a skidded system is a great solution. If you prefer to move the system by hand, a Rolling A-Frame is a great solution. If you are planning on moving the system by hand, be sure you have at least two workers available to push the system by hand from one point to another.

Step 4: Fall Protection Models:

After you have decided whether your application requires a mobile or permanent solution, and you have taken system specifications into consideration, you can begin exploring the different fall protection systems that meet your specific application. If you still feel like you could use some help selecting the right fall protection system, contact a local Rigid Lifelines’ representative today to schedule an onsite assessment.

To learn more about maximum arresting forces and how they impact your fall protection system and your workers, check out our post OSHA VERSUS ANSI. The last paragraph provides additional information about G-forces and the threshold for possible injury in the event of a fall.

Click here for information about your structure’s anchorage requirements.

Click here for information about the fall protection pyramid and implementing the appropriate form of protection for your operation!

Categories

Share this post

Let us help you

Contact us today to find the perfect product fit for your job