The Fall Protection Pyramid: Implementing The Appropriate Form of Protection for Your Operation

March 6, 2015

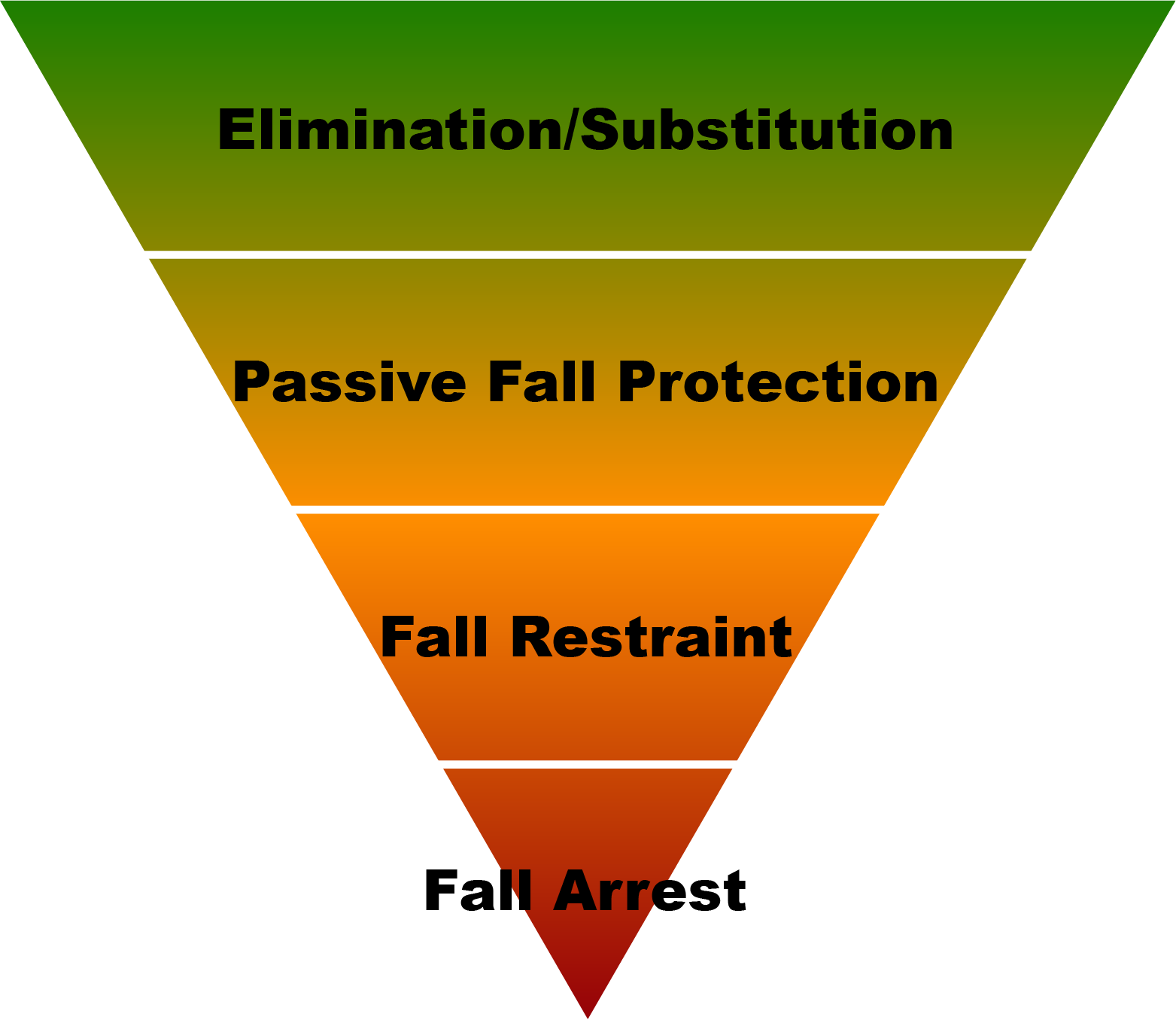

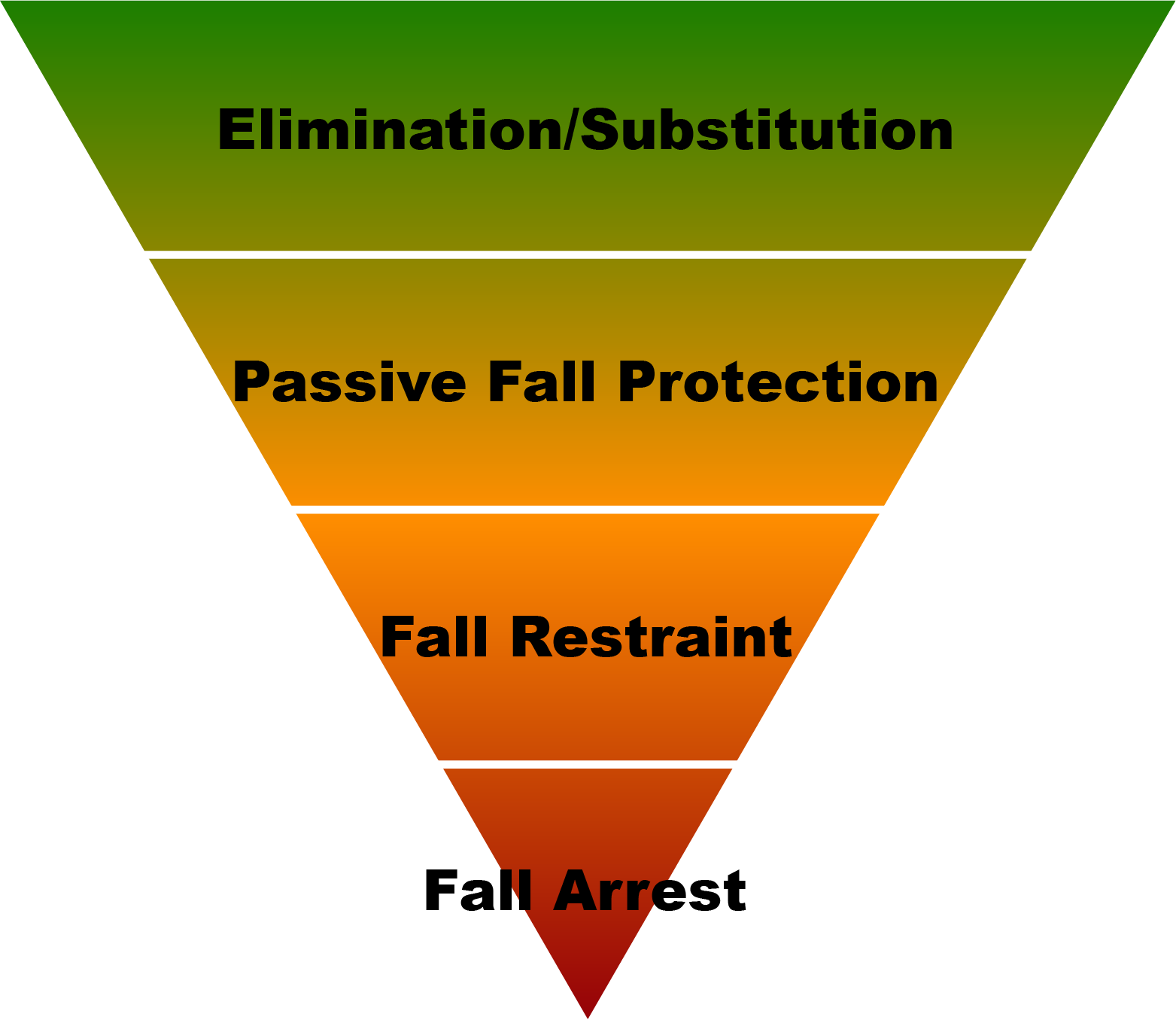

Although fall protection, fall restraint, and fall prevention are similar in concept, there’s a distinct difference between the three of them. This post aims to outline their differences and highlight the benefits of each using a systematic pyramid often referred to as the Hierarchy of Fall Protection.

ANSI (The American National Standards Institute) and ASSE (The American Society of Safety Engineers) developed the Hierarchy of Fall Protection (also known as ANSI-Z359) to help companies plan ahead and perform an exhaustive job hazard analysis. It strongly resembles the Hierarchy of Controls established by OSHA. Multiple governing bodies accept both hierarchies as the preferred order of control to eliminate or reduce fall hazards. This system reflects common safety practices for removing hazards from the workplace—beginning with methods of elimination and ending with training and administrative controls.

Before delving into the Hierarchy of Fall Protection to decide which method is best for your operation, it’s important to note that the first step to effectively implement the Hierarchy is to conduct an elevated worksite analysis. An elevated worksite analysis should be conducted by a qualified person, and should be used to identify all fall hazards. Doing so will allow you to consider options for reduction based on regulatory requirements and fall protection standards.

The Fall Protection Hierarchy:

1.) Elimination or Substitution: in regard to this particular hierarchy, eliminating the risk means avoiding work at height when possible or preventing people from reaching the fall hazard by creating a barrier between the person and the fall hazard. This is the most ideal means of preventing workers from a potential fall. But, oftentimes it’s not a practical option.

Effective elimination or substitution begins with a thorough evaluation of the workplace to determine if it’s possible to modify company practices and procedures or to change equipment and locations to eliminate exposure to any and all fall hazards. One example of elimination is to design warning lights or light fixtures that can be lowered to a safe location. In this case, workers can make repairs or replace bulbs without having to climb a ladder or use a lift.

2.) Passive Fall Protection: passive fall protection, also known as Engineering Controls, is still a form of preventative fall protection. It’s an excellent solution for workers who have to access rooftops or platforms, where equipment like handrails, safety gates, guardrails and rooftop railings are installed to prevent potential falls. Passive fall protection systems are extremely valuable for workers at height. If working at height is required, this form of fall prevention helps to ensure that workers are not exposed to unnecessary risks.

Railings are a very popular and effective form of passive fall protection because they protect workers without them having to put something on, adjust it, or actively inspect it. Railings are considered passive because a fall does not need to occur for them to protect you. This option is ideal in certain situations, and yet it tends to be overlooked too often. Passive Fall Protection and Engineering Controls are actually very cost-effective, and, when used correctly, can keep workers from ever having to experience a fall—arrested or not.

3.) Fall Restraint: fall restraint is a form of active fall protection—because the worker is connected to a lanyard and anchorage point. It is designed to do exactly what it’s called: restrain a fall. Protecting against the actual fall means that no arrest is necessary—and that means potential injuries can be easily avoided.

Fall restraint systems prevent workers from reaching a fall hazard using a tie-off system. When used properly, they prevent the human body’s center of gravity from reaching the fall hazard. These systems are generally comprised of personal protective equipment that is used to restrict the worker’s range of motion, ultimately preventing him/her from physically traveling to the fall hazard.

Fall restraint methods are a very useful form of fall prevention because they allow workers to perform their jobs without coming into contact with an unprotected edge. In this case, workers wear a harness, and then attach a fixed length strap to the harness D rings and an anchorage. Fall restraint systems are most suitable for workers who need to access the edge of a hazard, but they’re often overlooked and underused because they haven’t been fully integrated into many regulations.

4.) Fall Arrest: while the first three legs on the hierarchy are methods of fall prevention, fall arrest (also known as PPE) is a form of fall protection. Fall protection is used to arrest a fall, should one occur. It’s also a form of active fall protection, because workers are attached to a lanyard. But, it’s much less preventive than using a fall restraint system. Fall arrest systems are an essential tool for workers at height when fall prevention just isn’t feasible. Fall protection saves lives everyday. But, it doesn’t prevent the fall from actually occurring. It does help to prevent injuries and fatalities, but it’s designed to address the symptoms associated with a potential fall, not the actual problem.

There’s a great need for fall protection in many industries—particularly for people working at height in an environment where fall prevention is not a viable solution. Fall arrest equipment is designed using custom fitted equipment, and provides maximum freedom of movement. This allows workers to reach a point where a fall could potentially occur. If a fall should occur, the equipment will stop it in progress, allowing it workers to execute a self-rescue or to be rescued.

Arresting a fall is not as ideal as preventing one, but in cases where fall prevention is not possible, fall arrest equipment is critical to protect workers from injury or death. Examples of fall arrest equipment include: an anchorage or fixed structure with a coordinating connector, a full body harness, a lanyard to connect the harness to the anchorage, and a deceleration device to absorb the forces that occur during a fall arrest.

5.) Administration Controls: implementing thorough administrative controls is one of the best ways to prevent falls. Administrative Controls directly effect workplace policies and procedures. They involve adequate training, education, and safety regulations for all employees who have to work at height. Administrative controls are often described as, “Changes that reduce the duration, frequency, and severity of exposure to hazardous situations”. Administrative controls—like proper training, safety regulations, safety monitors, warning lines, designated areas, and control lines—can make tasks safer and reduce the risk of workers encountering a fall hazard.

In order to implement administrative controls, companies can hire trained safety professionals to educate their employees and integrate safety techniques that are lifesaving. Employers can also train their team through videos and content from OSHA, ANSI Z359.2-2007, the American Ladder Institute, or Ladder Safety Hub. Training your employees will teach them to be aware of potential hazards, allowing them to evaluate all tasks around the workplace, and to use fall protection/prevention equipment consistently and effectively.

Overall, elimination is by definition the most effective form of fall prevention. Even so, it can also be the most difficult form of protection to implement. Still, elimination should be taken into consideration whenever possible and before considering other forms of fall protection. Unfortunately, elimination is not always a realistic preventative method. Oftentimes, there’s just no other way to accomplish the necessary work without exposing workers to a fall hazard. That’s exactly why nationally recognized fall protection hierarchies like this one exist. When elimination is not an option—and it often isn’t—employers can move down the hierarchy, one-by-one, until they’ve found the right solution for their needs. The most important thing employers can do is whatever is takes to ensure that workers at height are safe from hazards.

Categories

Share this post

Let us help you

Contact us today to find the perfect product fit for your job