Fall Protection Forum

Recent Posts

June 20, 2025

Fall Protection for Icy Conditions

Cold Weather Safety When winter sets in, it doesn’t just introduce freezing…

May 19, 2025

ANSI Z359.2: Training for Authorized Rescuer vs. Competent Rescuer

As workplace falls increase in industrial and construction facilities, more employers are installing fall protection systems. While many employers will…

May 1, 2025

What is ANSI?

The American National Standards Institute, or ANSI, is an independent, non-profit agency that oversees the development of voluntary consensus standards for various industries. The agency works to ensure consistency and safety, as well as to assure worldwide acceptance of common standards, applicability, and terminology. ANSI also accredits standards developed by…

April 28, 2025

Understanding Suspension Trauma

Let’s look at suspension trauma, also known as harness trauma. Very simply stated, suspension trauma is injury or death caused by blood flow restriction while hanging suspended in a harness waiting for rescue assistance. This is why self rescue is so important. As required by OSHA law: 1910… So let’s…

April 25, 2025

What is Galvanization?

Here at Rigid Lifelines™ we frequently recommend that customers have their fall…

April 25, 2025

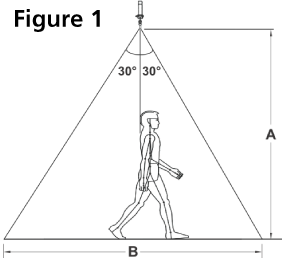

What Are Swing Falls and How Do They Occur

Swing falls in the industrial work place can result in significant injuries…

April 17, 2025

Passive vs. Active Fall Protection

Falls are serious hazards, especially in environments where workers perform their duties…

April 15, 2025

The Evolution of Horizontal Fall Protection

The fall protection industry is evolving. In its earliest form, workers used hemp ropes to tie around their waists in the event of a fall. During the latter part of the 20th Century, advances in technology took the concept of a rope and put it overhead in the form of…

March 28, 2025

Three Types of Workplace Falls

When looking to identify and address fall hazards in any working environment, it is important to understand the different types of falls that a worker may face while performing their daily tasks. Falls can be categorized into three types: falls on a single level, falls to a lower level, and…

March 17, 2025

ABCD’s of Fall Protection

Personal fall arrest systems, or PFAS, include anchorage, body support or body…

February 3, 2025

System Selection Guide: How to Choose the Right Fall Protection System

If you’re looking to install a comprehensive fall protection system for workers,…

February 3, 2025

Common Fall Protection Dangers Equipment Misuses

It’s always important to provide fall protection for people working at heights. OSHA requires fall protection any time someone is working four feet above the ground or higher for general industry or six feet or higher for construction. But it’s not enough just to have fall protection equipment: that equipment…