Maximum Arresting Force

July 24, 2025

Maximum arresting force (MAF) plays an important role in the safety of anyone who uses a fall protection system or device, as it determines how much force a user will experience when the fall protection system stops a fall. Considering that the Occupational Safety and Health Administration (OSHA) consistently places falls as one of the leading causes of fatalities in construction, understanding MAF and how to implement it is key to compliance and safety.

Understanding MAF

Maximum arresting force is the highest amount of force you will feel when your fall protection system stops a fall. You can think of MAF as that big jolt your body experiences when the system catches you. As you can imagine, experiencing excessive force places great strain on your body. To reduce the risk of injury, it is crucial to understand the maximum force the body can experience with fall protection systems.

The Science Behind Fall Protection Systems

The deceleration device in a fall protection system controls the most arresting force a person experiences. The amount of arresting force that a deceleration device exerts is typically established during the manufacturing process.

The arresting force of an energy-absorbing lanyard (also known as a rip stitch lanyard) is established during the stitching process. The more stitches there are in the fabric, the higher the force that the lanyard will exert during deceleration. Meanwhile, the arresting force for a self-retracting lifeline (SRL) is determined by the amount of torque that is placed on the main bolt in the center of the ratchet pawl device. A higher amount of torque on the bolt will result in a higher arresting force being exerted, whereas a lower amount of torque will lower the arresting force.

The flip side of the arresting force of individual fall arrest lifelines is that lifelines with a lower arresting force require greater distance to come to a complete stop. A longer stopping distance spreads the deceleration force over a greater span, which can reduce both the average arresting force and the maximum arresting force.

The physical science for fall protection systems is important because it ultimately determines how much bodily damage people will experience in the event of a fall. The numbers get more complicated if the fall protection system uses a wire as an anchorage point instead of a rigid track. Wire systems get more complicated because you need to factor in deflection rates and distances in addition to the force and deceleration speed of the deceleration device. Consult a safety professional to help you determine the right fall arrest solution for your system to minimize the risk of injury due to arresting forces.

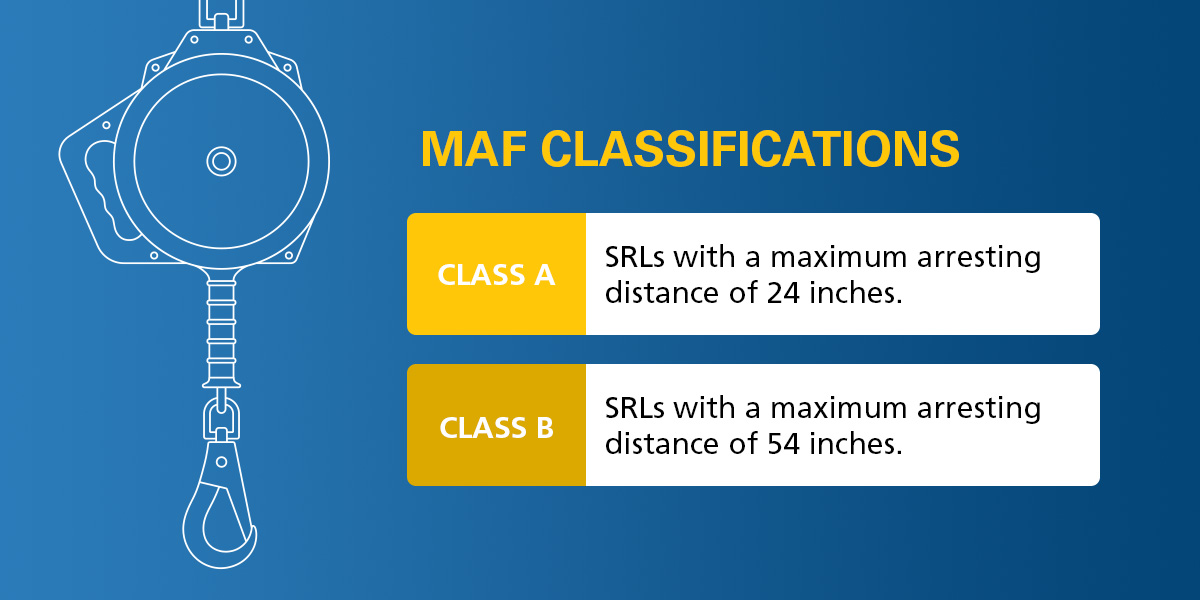

MAF Classifications

SRLs with a maximum arresting distance of 24 inches are classified as Class A, while SRLs with a maximum arresting distance of 54 inches are classified as Class B. Both Class A and Class B have an MAF of 1,800 pounds, but a Class B SRL may produce a lower overall arresting force. Additionally, the MAF may not be reached in an actual fall event, depending on the circumstances, so a Class B SRL can further reduce the actual force felt by a worker during a fall event. Class B SRLs should only be used when the distance to a lower level allows a sufficient factor of safety for a 54-inch maximum arresting distance.

History of MAF in Fall Protection

The earliest recorded fall protection tests occurred in Sweden and the United Kingdom around the time of WWII (mid to late 1940s). These tests were performed for aviation purposes in order to determine the different ways that the human body was affected by negative acceleration (or deceleration) forces. Scientists wanted to identify the level of damage the human body would experience during the deceleration forces exerted by ejection seating from airplanes. During their tests, they would use human spines from cadavers to test the different effects of deceleration forces. European studies revealed that 3,600 lbs of pressure would typically result in either serious injury or death.

By 1979, OSHA had decided that 1,800 lbs for maximum arresting force on fall protection devices was an acceptable limit. They determined this number by dividing the damaging force established in the European studies in half. Although full-body harnesses were available for use with fall protection systems, body belts were still the most commonly used harnesses. As a result of the limited use of a full body harness in industrial and construction settings, OSHA ultimately decided to reduce the allowable maximum arresting force of a fall arrest device to 900 lbs maximum arresting force.

In 1991, the 900 lb maximum arresting force became an industry standard. OSHA decided to change this standard because of the potentially lighter-weight people who may be using a fall arrest device. A person who has less body mass will experience a higher gravitational force when their fall is arrested. If a deceleration device has a higher maximum arresting force, in turn, it will exert more force on the body it is arresting. So, putting a lighter-weight person on a deceleration device with a higher maximum arresting force will dramatically increase the amount of gravitational force exerted on their body.

Under those particular circumstances, the amount of gravitational force administered could potentially cause serious injury or death to the person using the system. As a result of that higher potential for severe injury, OSHA decided to reduce the limit on maximum arresting forces to better ensure the well-being of lighter-weight persons who were using a fall arrest deceleration device. Although OSHA still allows body belts to be used for fall protection, body belts are now only allowed to be used in very specific fall protection applications. As of 1994, OSHA only allows a deceleration device to be used in conjunction with a full-body harness for fall arrest.

Why Maximum Arresting Force Is Important

Maximum arresting force plays a core role in fall protection systems for several reasons:

- Reduces injury risk: If the force you experience when a fall protection system stops you is too high, you can be seriously injured from the force, even when you have a harness on. A lower arresting force places less stress and strain on your body and can reduce your risk of internal injuries, broken bones, and other types of trauma.

- Ensures greater compliance: Using fall protection systems that comply with OSHA’s strict limits is a must for remaining compliant. OSHA’s limit is 1,800 pounds for a full-body harness.

- Shows system performance: MAF is a good indicator of how well a fall protection system is designed and produced. Well-designed fall protection systems will keep arresting forces low.

- Impacts on rescue and recovery: A fall can be a traumatic event. It takes time to recover, both physically and mentally. Thankfully, experiencing lower forces during a fall can reduce the risk of serious trauma, making the rescue potentially easier and recovery smoother.

OSHA Maximum Arresting Force Regulations and Compliance

OSHA 1910.140(d)(1) provides the system performance criteria for a personal fall arrest system. This section states that “the employer must ensure that personal fall arrest systems must: (i) limit the maximum arresting force on the employee to 1,800 pounds (8 kN).

This figure is based on the use of a full-body harness. OSHA 1910.140(b) requires the use of a harness that will “distribute the fall arrest forces over at least the thighs, pelvis, waist, chest, and shoulders.” This requirement means that climbing harnesses that secure only the waist and thighs, like those used in recreational climbing, are not acceptable for use with a personal fall arrest system.

OSHA’s guidelines and regulations for compliance extend beyond OSHA 1910.140(b). To be compliant, employers also have the responsibility of selecting the right fall protection systems and installing and maintaining systems in a way that meets industry requirements. Employers must ensure these systems undergo regular inspections, and any workers using fall protection systems have regular training.

Another important compliance consideration is that all fall protection equipment is clearly labeled with its maximum arresting force rating and other safety specifications.

Explore Fall Protection Systems From Rigid Lifelines®

Understanding the importance of maximum arresting force in fall protection systems is key to greater safety and compliance. At Rigid Lifelines, we manufacture quality mobile and permanent fall protection systems that meet industry standards. We also manufacture a variety of fall arrest accessories, including Full-Body Harnesses, Cable Self-Retracting Lanyards, and Cable Hybrid Self-Retracting Lanyards.

Our products are distributed across the United States, Canada, Mexico, and Latin America. You can contact a local representative to assist you in exploring fall protection systems that best suit your projects. You can also contact your local Rigid Lifelines rep to schedule an on-site assessment for tailored fall protection systems and solutions.

Categories

Share this post

Let us help you

Contact us today to find the perfect product fit for your job